Return ×

Thanks for the address

Will contact you within 3 hours.

+7 (495) 783-01-67

+7 (495) 783-01-67

Purpose

Polymeric liners (PEV type) are designed for impermeable storage of crude oil, diesel fuel, chlorine, acids, caustics, water, liquid mineral fertilizers and food liquid products.

Sphere of application:

According to experts, currently 70% of the tanks that are intended for storage of oil products in Russia are tanks with the age of 20-30 years. Sometimes the reconstruction of equipment that has already finished its service life is more economically feasible than the construction of a new one. This is especially true for high-capacity metal tanks, as their dismantling and disposal entail many problems.

Company JSC NPF "Politechnika" offers you to use innovative technology to extend the service life of metal and concrete tanks with the use of soft polymeric materials.

Materials

Polymeric liners (PEV type) are made with advanced technologies of high-strength polymer composite elastomers coated with PVC, TPU, PVDF, PVDC, LLDPE, HDPE, depending on the type of aggressive substance stored. They consist of polyester fabric and represent a closed cylindrical shell with a technical manhole (hatch) mounted in it for connection to the system, they can also be of cylindrical shape with an open top.

Modifications of liners:

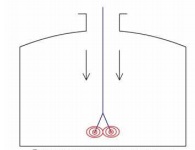

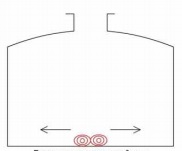

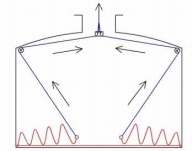

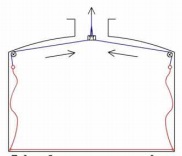

Installation of liners:

|

|

|

|

|

1. The soft polymeric liner folded in a roll is put in the tank using the crane. |

2. The liner shell is unfolded on the bottom of the tank. |

3. The shell is fixed along the perimeter of the bottom of the tank and on its technological parts. |

4. The side panel shell of the liner is raised to the walls and fixed on the edge of the roof and parts of the walls of the tank using the lifting blocks and winches temporarily mounted on the edge of the roof of the tank. |

Prior to installing a polymeric liner (PER-SV type) it is necessary to perform following operations:

cleaning of surfaces to the required degree, phosphating the inner surface of the tank (creation of chemical corrosion-resistant film of insoluble phosphate);

inspection of wall thickness with non-destructive testing methods for compliance with regulatory requirements;

application of primer or polymer compositions (optional).

The advantages of using polymeric liners (PER-SV type) compared to alternative technologies to majorly repair and reconstruct the tanks: